Progettazione e assemblaggio di soluzioni di sistema

In molti stabilimenti chimici, spesso le soluzioni di sistema I/O standard non sono sufficienti. Con una ricca gamma di esperienza e capacità con cui il fornitore medio di prodotti di automazione, semplicemente, non può competere, Turck offre soluzioni di I/O complete semplici da installare e totalmente affidabili.

VANTAGGI

- Gestione semplice dei progetti – Turck garantisce soluzioni di sistema personalizzate

- Zero compromessi – Le soluzioni per la connettività e i sistemi possono essere modificate in base alle specifiche esigenze di ogni applicazione

- Le soluzioni per i sistemi I/O possono comportare delle fasi di progettazione, produzione, test e installazione

In questa sezione

- Automotive

- Modular Flexibility and Safety in Filter Production

- Cable with Integrated Current Monitoring Prevents Unwanted Shutdown of Conveying System

- Inductive Couplers Ensure Precise Material Feed

- Assembly Management with a Direct MES Connection

- Body Detection in Automobile Production

- Reliable Skid Detection in Automotive Production

- Error-free JIS Order Picking for Bumpers

- Laser Sensor Detects Shiny Sheet Metal Cylinders in Battery Production

- Level Measurement in Dip Coating Line

- Level Control in Central Lubrication System

- Quality Assurance on the Gluing Robot

- Tilt angle sensor accelerates platform alignment

- Motor Control with Condition Monitoring

- IP67 Hybrid Module Processes Safety Signals

- Decentralized monitoring of cooling stations

- Monitoring the cooling circuit on welding clamps

- Flow monitoring in drum washers

- Sheet Metal Thickness Measurement

- Condition Monitoring of Motors

- Cloud-based level monitoring

- Press Shop – Tool Identification

- Body Shop – Welding Nut Detection

- Paint Shop – Skid Identification

- Final Assembly – Robot Assembly

- Powertrain – Contactless Verification

- Area Guarding for Robotic Cells

- Item-level Detection with UHF RFID

- Supply of cooling lubricant in machine tools

- Controlling hydraulic pressure in pressing plants

- Measuring process pressure on scissor lifts

- Inspection of Tips on a Welder

- Manual Feeding in Weld Cell

- Detecting Black Parts on Black Door Panel

- Moonroof Clear Glass Detection

- Long-Range Inspection in Automotive Assembly

- Rubber Washer Detection on Engine Block

- Engine Block Part-In-Place Detection

- Electric Vehicle Detection in Charging Station

- Vehicle Detection in a Self-Serve Car Wash

- SUCCESS STORIES

- Modular Plant for Flexible and Efficient Production

- Laser Sensor Detects Black Bumpers in Assembly Cell

- Decentralized Safety Technology for Modular Production

- Modular Conveyor System

- RFID and I/O Modules for Safe Tool Changes

- RFID Guides AGV in Suspension Production

- IO-Link Wired Silencer Production

- Workpiece Carrier Identification in Rear Vent Production

- Weld Nut Sensing

- RFID Traceability

- RFID in Engine Production

- Bumper Production with Identification

- Solutions for Paint Shops

- Welding and Assembly Sensors

- Angle Sensors for Assembly Systems

- Tool Identification

- Pick-to-Light for Bumper Assembly

- RFID Identification of Injector Nozzles

- RFID in the Body Shop

- IO-Link Eases Differential Gear Production

- Ply Orientation Inspection

- Chemical

- excom I/O System Enables Safe Hydrogen Liquefaction

- Decentralized Automation in Ex Areas

- RFID Control of Tube Connections in the Ex Area

- Ethernet Signal Connection in the I&C Room

- Ethernet-based Automation of Modular Skids

- Ex Isolation in Modular Process Plants

- Detection of Pigs

- Remote Tank Level Monitoring with DX70

- Remote Signal I/O

- Easy Connection of Field Devices

- Signal Processing with System I/O in the Control Cabinet

- Signal Separation with Interface Technology in the Control Cabinet

- Identification of Hose Connections

- Efficient Monitoring of Cabinets in the Field

- Monitoring of Quarter Turn Actuators

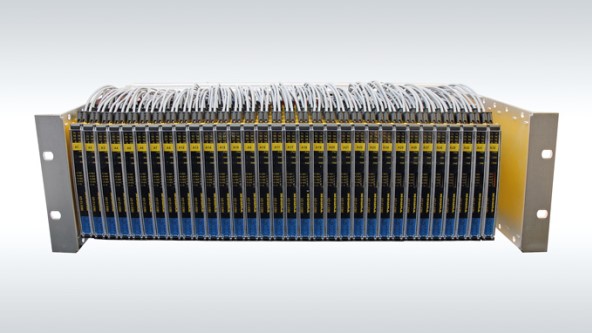

- Planning and Assembly of System Solutions

- Success Stories

- Control Cabinet Monitor for Transmission of Condition Data

- I/O System Excom Creates Space in the I&C Rooms

- Zone 2 and 22 RFID

- Efficient Testing Control

- Intrinsically Safe Field Communication

- Process Control System Partnership

- Hazardous Area Remote I/O

- Dual Valve Position Feedback

- Flexibility with Fieldbus

- Asset Management with Remote I/O

- Correct Positioning with RFID in Carbide Production

- Fast conversion in restricted space

- Energy

- RFID System Identifies Solar Cell Carriers

- Decentralized I/O System for Hazardous Areas at H2 Refueling Stations

- Decentralized I/O Solution in Ex Zone for H2-Fueling Station

- I/O Module Facilitates Setup and Mobile Use of Fuel Cell Test Stand

- Wind Turbine Rotor Positioning

- IP67 I/O in Coal Production

- UHF RFID Identifies Switch Gear

- Remote I/O in Biogas Plant

- Food and Beverage

- RFID Tracking Reduces Food Waste in Ice Cream Production

- Dough Height Inspection for Accurate Measurement

- Dough Thickness Control in Rolling Machines

- Leading Edge Detection of Plastic Container

- Identification of Food Containers

- Container Check

- Date/Lot Code Verification

- Detection of Valve Position

- Detection of Pipe Elbows

- Identification of Chocolate Moulds

- Barcode Reading on Depalletizer Station

- Success Stories

- Cloud-based Maintenance for Steam Generators

- RFID Support Enables Track and Trace in Food Production

- Grist for the Mill

- Decentralized Control Modules in Coldstore

- Track and Trace in Meat Production with RFID

- Contact-free Encoder in Potato Production

- UHF RFID in Food Distribution Center

- RFID for Chocolate production

- Distributed I/O for Food Equipment

- Remote I/O for Distilleries

- RFID and Autoclaves

- Transparency in Chocolate Manufacturing

- IP67 Power Supplies for Conveyors

- Identification in Food Product Storage

- Detecting Refrigerated Breakfast Rolls on a Multi-Lane Conveyor

- Reliable Cap Orientation Verification in Aseptic Areas

- Clear and Tipped Bottle Detection on Depalletizer

- Clear Plastic Bottle Detection

- Frozen Food Packaging Label Inspection

- In-Line Bottle Accumulation on Single Filer

- Logistics

- Monitoring Cooling and Lubrication Circuits in CNC Machines

- Height Control and 3D Spatial Monitoring on Autonomous Forklift Trucks

- Decentralized Control of Conveyor Modules

- Tracking Big Bags with RFID

- Distance Detection in Container Cranes

- Access Control for Protected Areas

- Decentralized Muting of Electro-sensitive Protectice Equipment

- I/O Blocks Control Roller Conveyor Modules

- Container Check

- Fast Tag Detection at Warehouse Gates

- Item-level Detection with UHF RFID

- Preventive Maintenance on Conveyor Belts

- Detection of Transport Containers

- Level Detection in Vessels

- Identification of Cryovessels

- Identification of Mobile Containers with Handheld Devices

- Identification of Food Containers

- Tier 1 – Bumper Identification

- Condition Monitoring in Storage Rooms

- Collision Protection on Reach Stackers

- Success Stories

- Reliable AGV Control through Sensor-based Complete Solution

- Sustainable Tracking of RTIs thanks to RFID

- RFID Solution for Error-Proof Material Logistics

- RFID with HF Bus Mode Eases Seed Storage

- Pick-by-Light accelerates manual logistics by over 60 percent

- Pick-by-light Solution Facilitates Assembly Processes

- RFID Enables Unmanned Store at Major Building Site

- I/O and Safety Modules Increase Throughput in Intralogistics

- Shipment Tracking for Raw Materials

- RFID-Based Tracking Solution for Loading Error Minimization

- RFID-based Tracking of Inbound and Outbound Materials

- Decentralised UHF RFID Solution

- Contact-free Encoder in Potato Production

- Decentralized Control Modules in Coldstore

- Speed Control via Radar Sensor QT50

- IP67 Power Supplies for Conveyors

- Modular Conveyor System

- RFID Solution for Warehouse

- RFID Guides AGV in Suspension Production

- RFID Identifies Pharmaceuticals

- UHF RFID in Food Distribution Center

- Autonomous Parking Assistance for Trucks

- Mobile Equipment

- Animal and Object Detection on the Combine Harvester

- Loading Dock Occupancy Monitoring

- Monitoring Railcars Wheels Wirelessly

- Automatic Slope Compensation

- Distribution Lines for Field Sprayers

- Reach Stacker Status With Bright Lighting Indicators

- Angle Measurement on a Field Sprayer

- Material Flow Monitoring on a Combine Harvester

- Determining the Boom Angle Position

- Vehicle at Loading Dock

- Wireless Forklift Signaling

- Equipment Compartment Illumination on Fire Engines

- Two-Axis Tilt Measurement on a Combine Harvester

- STS Collision Avoidance

- Success Stories

- RFID Solution with Smart Forklifts in Autombile Production

- Safe Remote Maintenance of Irrigation and Drainage Pumps

- Access Control with RFID System

- Selective Asparagus Harvester

- Position Measurement with RFID and Encoder

- Speed Control via Radar Sensor QT50

- RFID Guides AGV in Suspension Production

- Block I/O Modules on Super Yacht

- Wear-free Encoder on Hopper Dredger

- I/O for Dust Suppression

- Cabinet Cooling

- Quick Disconnect Connectivity

- Automation Solutions for Extreme Cold

- Remote I/O for Cranes

- Rugged Heavy Metal Lifting

- Rollercoaster Positioning

- Mobile Machinery Solutions

- Exact Height Positioning

- Critical Angle Sensing

- Predictive Maintenance of Machine Parts at Port-Based Coal Conveying Facility

- Angle Sensor Detects Platform Lift

- Oil and Gas

- Packaging

- Identification of Printing Color Cartridges

- Reliable Operation of Machines

- Monitoring of Caps in Filling Lines

- Monitoring Changeover Processes

- Identification of Test Bottles

- Box Insert Detection

- Level Monitoring of Ground Coffee

- Carton Dimensioning

- Success Stories

- Clear Container Detection

- Correct Label Verification

- Detecting Different Size Packages on a Conveyor

- High-Speed 2D Barcode Inspection

- Multicolored Reflective Package Detection

- Plastic Roll Diameter Measurement

- Tube Positioning Using a Registration Mark

- Vertical Form Fill Seal Machine Solutions

- Pharma

- End-to-End Sample Tracking with RFID

- RFID Control of Tube Connections in the Ex Area

- Decentralized package verification for pharmaceutical products

- Automate Modular Skids

- High-Speed Tablet Counting With Fiber Amplifier

- Pharmaceutical Skids with Decentralized I/O Technology

- Ex Isolation in Modular Process Plants

- I.V. Bag Liquid Detection

- Monitoring of Quarter Turn Actuators

- Detection of Pipe Elbows

- Remote Signal I/O

- Liquid Level Monitoring In A Large Tank

- Planning and Construction of Super Skids

- Easy Connection of Field Devices

- Identification of Cryovessels

- Identification of Mobile Containers

- Identification of Mobile Containers with Handheld Devices

- Identification of Hose Connections for Precursors

- Identification of Hose Connections in Sterile Areas

- Identification of Hose Connections in Ex Zone 1

- Identification of Big Bags and Bioreactors

- Identification of Single-Use Applications

- Semiconductor

- Electronic Marking Verification

- Counting Integrated Circuits

- Inspection of Two Barcodes

- Compact Safety Control

- Safeguarding Small Access Points

- Semiconductor Process Tool Illumination

- Adhesive Detection on PCB Assembly

- Wafer Center Detection with DF-G2

- Great Detail Inspection for Mobile Electronic Devices

- Error Proofing for IC Chips loaded into Pocket Tape

- Presence and Orientation of IC Chips Seated in Nests

- Detection of Hard Disks

- LED Status Indication During Semiconductor Manufacturing

- Safeguarding Small Access Points

- Success Stories